Project Overview

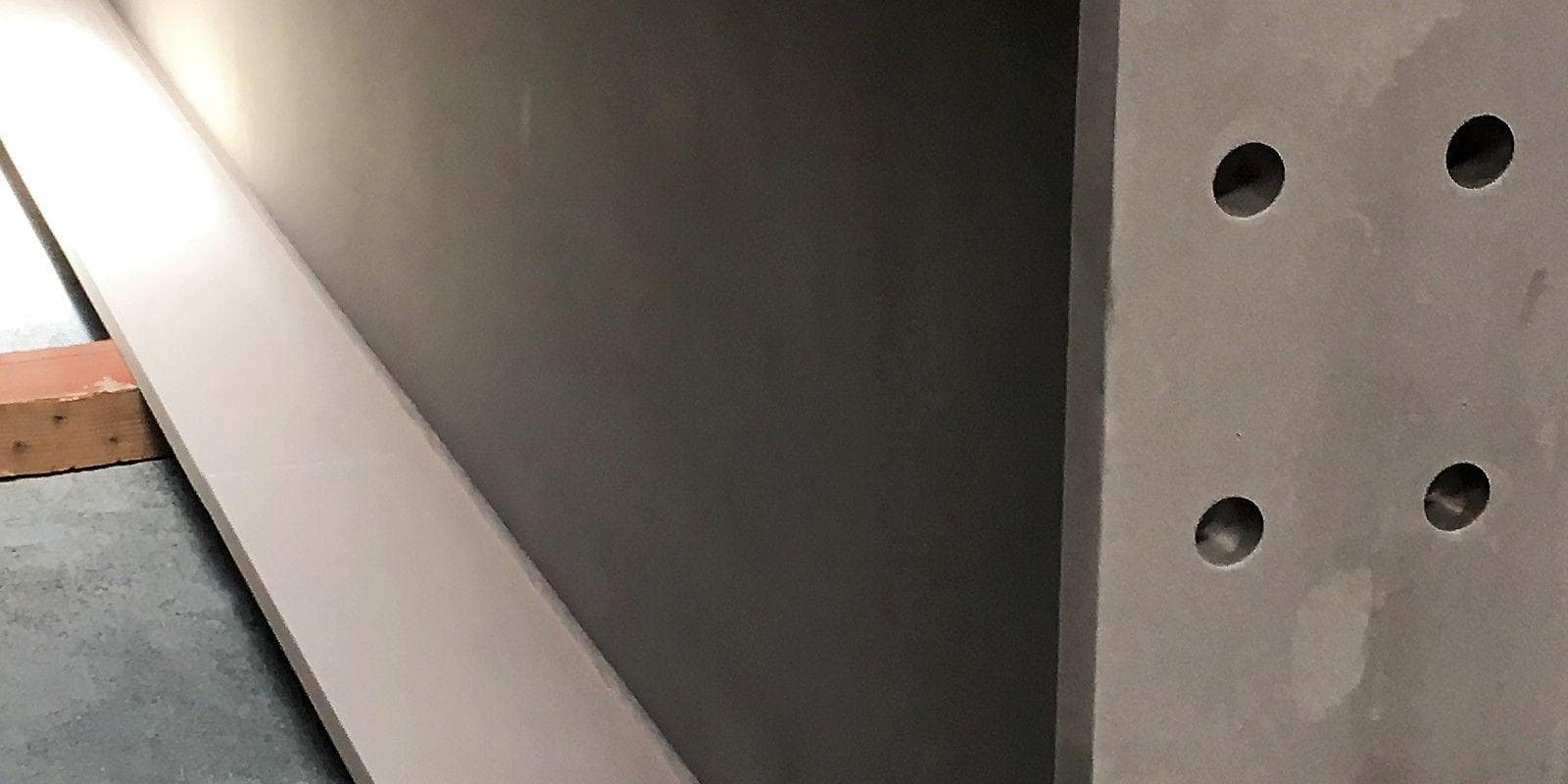

Strengthening of bridge 5179 and 5128 included fabrication and installation of welded steel beams at equal spacing between the existing concrete I-girders. Each beam was spliced, bolted together in situ, laterally restrained and mounted on fabricated steel bearing seating brackets. The project encompassed several highly technical elements, including the complex task of positioning the 16 tonne welded steel beam sections underneath the existing bridge structures.

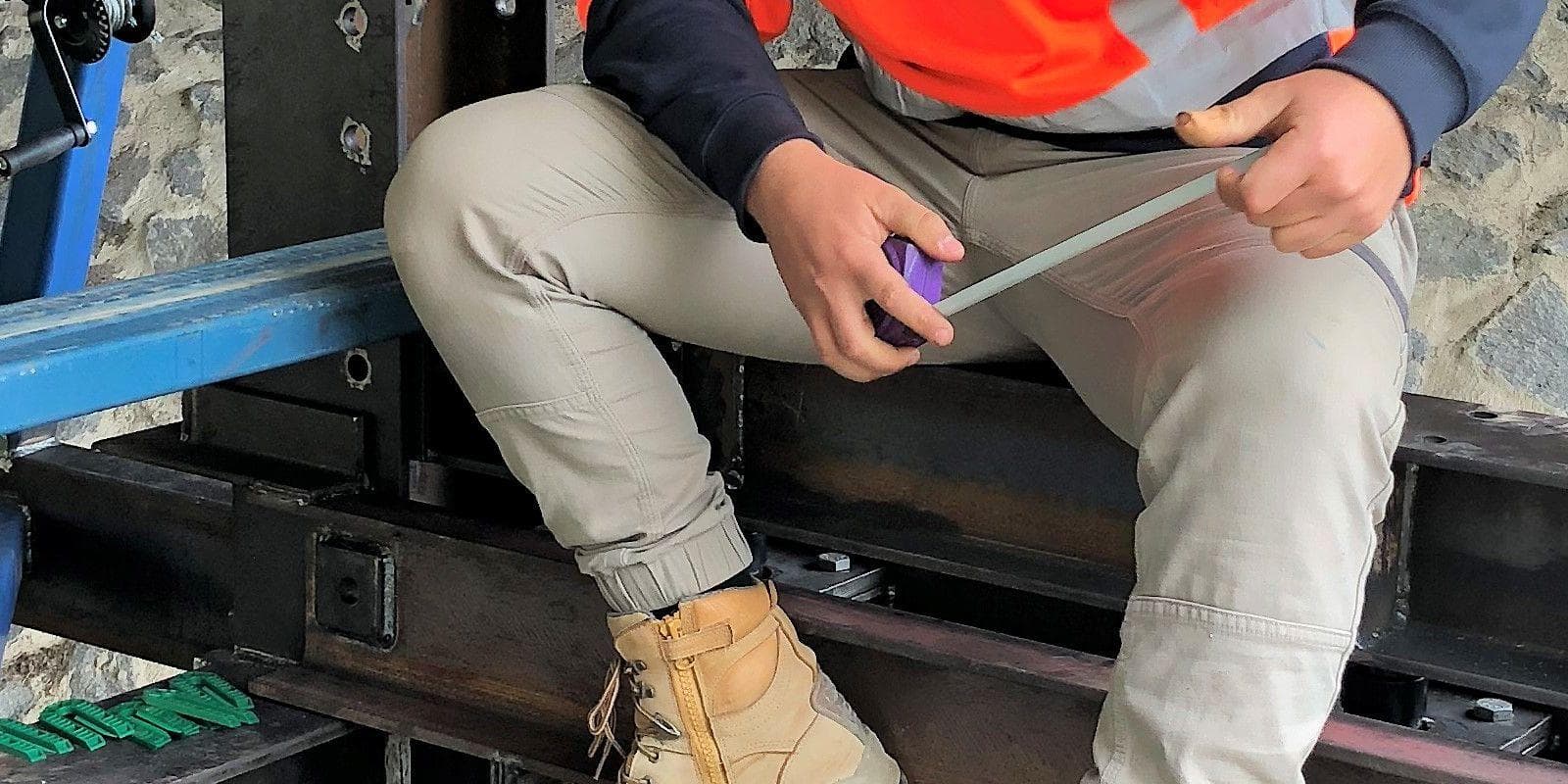

Complex developed a bespoke trolley system to allow each beam section to be transversely positioned into alignment, hydraulically jacked 2 metres, longitudinally shifted over the abutment shelf and bolted together in position. The initial concept was developed at tender stage and brought to reality by the highly skilled project delivery team, who added further functionality to the design by using the trolley as a platform and catch deck during overhead grouting operations between the steel girder and existing deck.

Project Features

- Waterways works licence

- Working in flood prone locations

- Fabrication, supply and installation of steel girders, bearing brackets and lateral - restraints

- GPR concrete scanning

- Temporary works design for complex lifting operations

- Complex scaffold access and load bearing requirements

- Bridge jacking and bearing replacement

- Working in a remote location

- Complex overhead grout pumping operations

- Crane lifting, lift studies and safety management

- Contact us

- Join the team

Let us know how we can help, get in touch via the form below.

We’re constantly on the lookout for new talent. If you like what you see and want to join our team, fill out the form below and we’ll get back to you as soon as we can.